Cost-efficient Techniques for Packaging Machine Repair and Upgrades

Cost-efficient Techniques for Packaging Machine Repair and Upgrades

Blog Article

From Advancement to Implementation: Utilizing the Power of a Modern Product Packaging Machine for Sustainable Growth

The fostering of contemporary packaging devices offers a substantial opportunity for organizations to improve operations, lower waste, and boost their general brand name credibility. The journey from conceptualizing ingenious packaging options to successfully implementing them in a way that drives lasting growth is a complex process that requires cautious consideration and tactical preparation.

The Function of Modern Product Packaging Machines

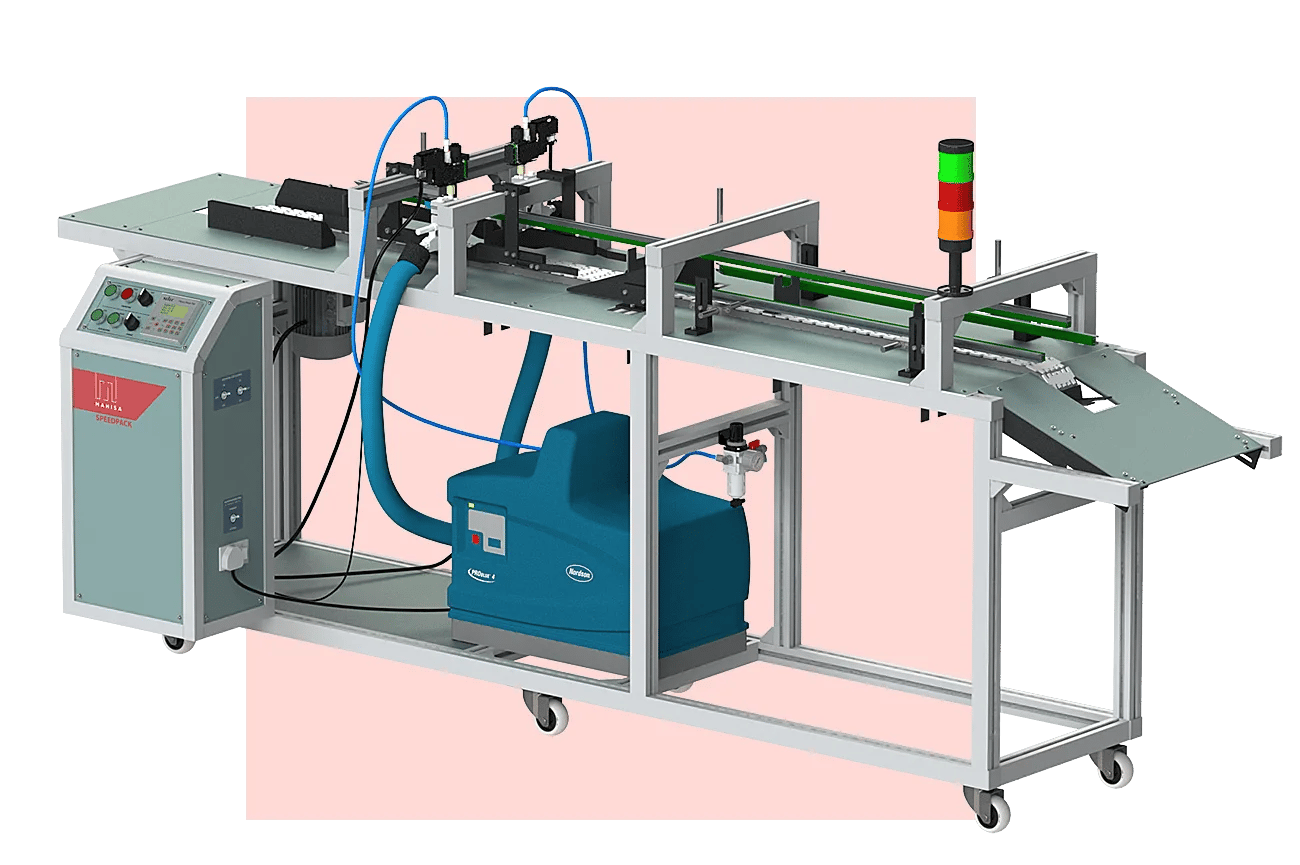

In today's busy industrial landscape, modern product packaging makers play a crucial function in enhancing effectiveness, consistency, and cost-effectiveness in the product packaging process. These sophisticated devices are designed to satisfy the growing needs of the market by improving procedures, lowering downtime, and ensuring product top quality.

One trick facet of modern-day packaging equipments is their capacity to enhance performance. By automating different stages of the packaging procedure, these devices can manage tasks at a much faster speed than manual work, bring about greater efficiency degrees. Additionally, the uniformity achieved via automation makes sure that each product is packaged with the same precision and high quality, minimizing the danger of mistakes or inconsistencies.

Cost-effectiveness is one more considerable benefit used by modern-day packaging equipments. While the preliminary financial investment might be higher, the lasting cost savings in labor prices, decreased material waste, and enhanced manufacturing result make these machines a clever financial investment for firms looking to maximize their packaging operations. In final thought, the duty of modern packaging makers is crucial in driving effectiveness, consistency, and cost-effectiveness in today's packaging industry.

Advantages of Sustainable Packaging Solutions

Using sustainable product packaging options uses a wide variety of advantages for organizations aiming to reduce their ecological impact while meeting customer needs for eco-friendly products. Lasting product packaging often entails the usage of recyclable products, naturally degradable options, and minimized product packaging waste, leading to reduced greenhouse gas emissions and total environmental effect. On the whole, welcoming lasting product packaging solutions not just benefits the world however likewise offers critical advantages for services looking to flourish in an extra eco-conscious market.

Implementing Green Practices in Production

The assimilation of ecologically conscious methods in manufacturing procedures is critical for modern services striving to lessen their environmental impact. Applying eco-friendly techniques in production entails embracing strategies that minimize waste, power consumption, and general environmental effect. One essential facet is the utilization of renewable energy resources such as solar or wind power to operate equipment and power production processes. In addition, implementing recycling programs within the production center can help lessen the quantity of waste sent out to garbage dumps.

An additional important element of green manufacturing techniques is the optimization of resources through efficient processes and innovations. This includes making use of innovative product packaging important link makers that are designed to lessen material use while keeping product stability. Employing lean manufacturing concepts can additionally add to lowering waste and improving total efficiency in manufacturing operations.

Moreover, integrating lasting products right into the production process, such as naturally degradable product packaging products or recycled content, can further improve the ecological sustainability of the organization. By integrating these environment-friendly techniques into manufacturing processes, services can not only decrease their ecological effect yet also show a commitment to sustainability that resonates with eco-conscious customers.

Enhancing Efficiency Via Technological Innovation

In addition, the application of clever technologies, such as Net of Points (IoT) data and sensors analytics, permits for real-time tracking of packaging procedures. This not this post only makes it possible for aggressive maintenance to avoid downtime however also offers beneficial understandings for maximizing process and resource utilization. Additionally, using robotics in product packaging operations can additionally improve performance by managing repetitive jobs with accuracy and consistency.

Lasting Growth Methods With Packaging Innovation

Along with ecological benefits, sustainable packaging approaches can also result in set you back financial savings in the lengthy run. Efficient product packaging layouts can lower product use, reduced transportation prices, and enhance production procedures, eventually driving economic savings for businesses. Embracing sustainable product packaging techniques can foster a favorable brand name photo, attract socially liable financiers, and develop an affordable side in the market. On the whole, the strategic combination of sustainable packaging technology is not only valuable for the earth yet also for long-term organization go right here growth and success.

Conclusion

In final thought, the role of modern-day product packaging makers is indispensable in driving performance, consistency, and cost-effectiveness in today's packaging market. - packaging machine repair

Sustainable packaging often involves the use of recyclable products, eco-friendly options, and decreased product packaging waste, leading to reduced greenhouse gas emissions and general environmental effect.Implementing sustainable growth methods via the assimilation of advanced product packaging modern technology is paramount for firms aiming to decrease environmental effect while increasing functional performance and productivity.In final thought, modern-day product packaging machines play an important duty in driving sustainable growth by offering benefits in efficiency and green practices. By applying technological advancement and sustainable product packaging remedies, businesses can enhance their production procedures and contribute to an extra ecologically pleasant future.

Report this page